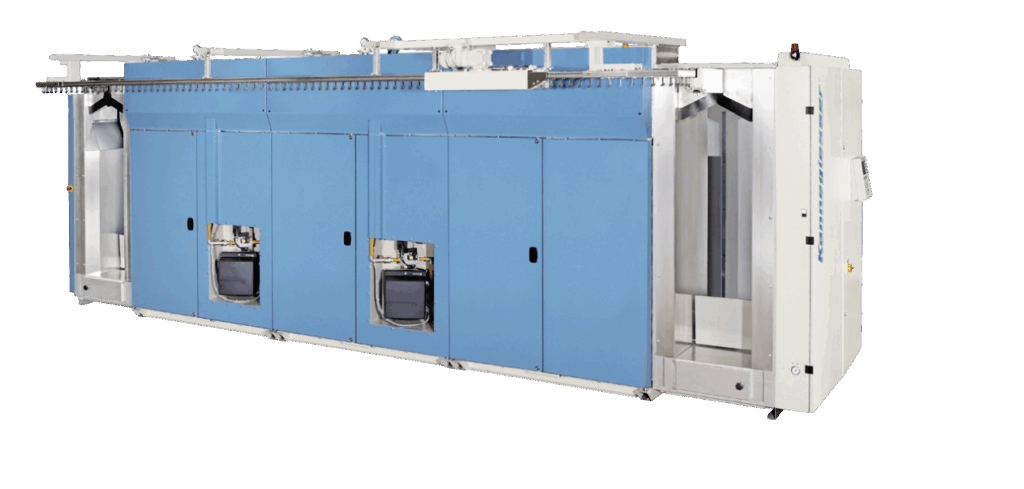

XMT

CONTINUOUS DRYING AND FINISHING IN ONE STEP

The XMT tunnel finisher is your solution for best finishing and drying results with a minimum of energy.

Customers demand an ever wider range of fabrics and article types with increasing requirements for finish quality. Textile services face the challenge of providing premium garment finishing while keeping energy costs low. The XMT’s innovative machine design and the use of counter air flow make it possible.

SUMMARY

Raising quality while saving energy

The XMT tunnel finisher handles every single piece of garment with upmost care while evenly smoothing and drying it swiftly. On top of that, the heat ist kept inside the system which reduces energy costs significantly.

- Highest specific output per sq ft

- Up to 2500 garments/h dried and finished – wet to dry!

- Superior finish quality due to complete air circulation for every single item

- Less energy consumption due to the only true counterflow principle for maximum energy yield

- Gentle textile treatment by means of incremental temperature control